This is the size of an average size pallet fork, which is nowhere near the smallest. Go ahead and put your finger over it for relative size.

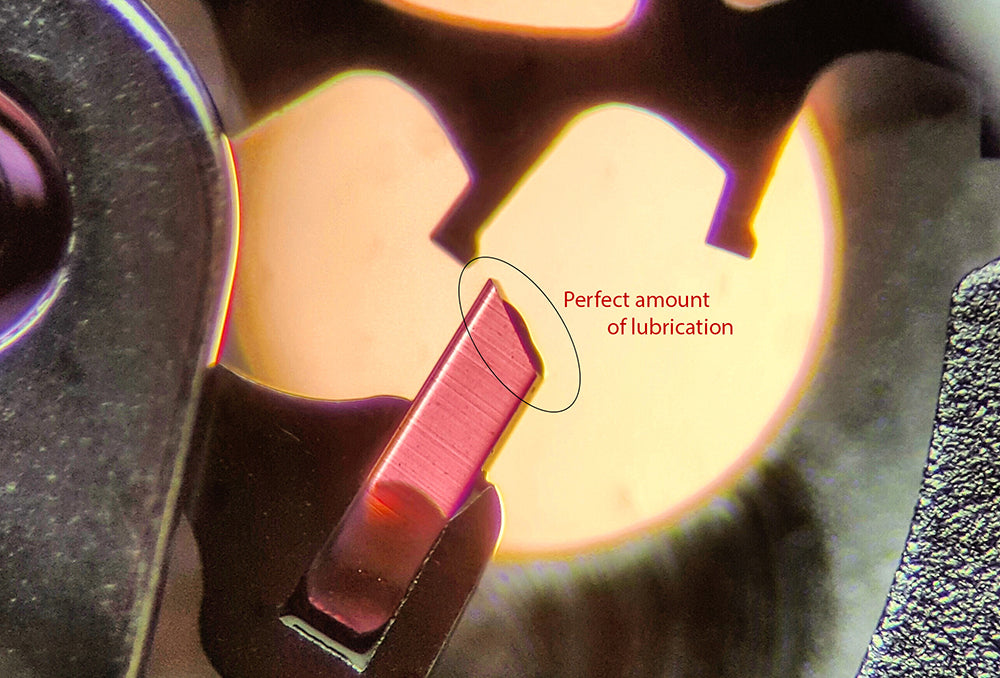

During assembly, a minute amount of lubrication is applied to the edge of the pallet stone utilizing the finest needle point applicator. Too much or too little lubrication and the watch will not work.

When the watch is set into motion for the first time, lubricant is taken from the pallet stone and trace amounts are spread across each tooth of the escape wheel. When applied correctly, this component will not need lubrication for another 4 or 5 years.

Its truly remarkable to think applications are possible by trained watchmakers today, let alone by watchmakers 200 years ago. The action above is just one of dozens of operations necessary to service even the most basic mechanical movements.